We use REVIT as our BIM platform. BIM allows us to plan and visualize the entire project from preconstruction through buildout. The creation of simulations and 3D visualizations allow us to visualize what the space will look like before beginning the project and make changes before construction even starts, minimizing expensive and time-consuming changes later. We invest heavily in the use of our Trimble Total Stations on site, which integrates with BIM and produces accurate 3D models.

-

- BIM allows for complete information creation and management of the workflow of our projects

- BIM also allows us to coordinate and share our information with all trades on the site

- BIM promotes better collaboration and communication between PEC and our trade partners

- BIM allows for model-based cost estimation

- BIM provides Virtual Project Visualization during preconstruction

- BIM’s clash detection supports project coordination with other trades and greatly reduces the need for change orders during the physical build which greatly reduces project costs and mitigates risk

- BIM has led to notable improvements in scheduling and sequencing

- BIM is responsible for the continuous increase in productivity by maximizing the use of our prefabrication department’s ability to design customized modular builds for our projects

- BIM enhances safety on the job by modeling through and visualizing hazards and potential problems of a project

- BIM gives us tighter control of technical decisions, resulting in a higher quality built project

Prefabrication

What is Prefabrication?

Prefabrication is the practice of assembling components of a structure in a controlled environment or manufacturing site and transporting complete assemblies or sub-assemblies to the construction site where the structure is to be located. The term is used to distinguish this process from the more conventional construction practice of transporting the basic materials to the construction site where all assembly is carried out.

What are the Benefits of Prefabrication?

1. Shorter Construction Time

Prefabrication allows for improved upfront planning, leading to a reduction in construction times when handling multiple projects at once.

2. Reduced Worksite Disruptions

In-house prefabrications reduce the volume and the number of deliveries to a site which allows work site crews to focus and concentrate on what they do best which is building and installations.

3. Consistent & Improved Quality

When constructing or assembling within a controlled environment you eliminate many of the outside variables such as weather, noise and space limitations associated with the common jobsite.

4. Enhanced Jobsite Safety

With in-house prefabrication you remove fluctuating weather conditions; moisture, noise, dirt, and general worker traffic on the site. This contributes to a more organized and safer jobsite.

5. Eco-Friendly

In-house prefabrication allows for the associated waste materials to be recycled or repurposed vs. sending those materials to landfill from a traditional jobsite. It also allows for commodities materials to be repurposed.

Lean Manufacturing

AT PEC, we strive to create value for our customers by reducing defects, eliminating waste and continually improving our process. From standardizing the way we build, to the way we order office supplies, we aim to reduce costs while optimizing and improving performance. LEAN has become a way of thinking and acting for our entire organization which ultimately adds value for our customer.

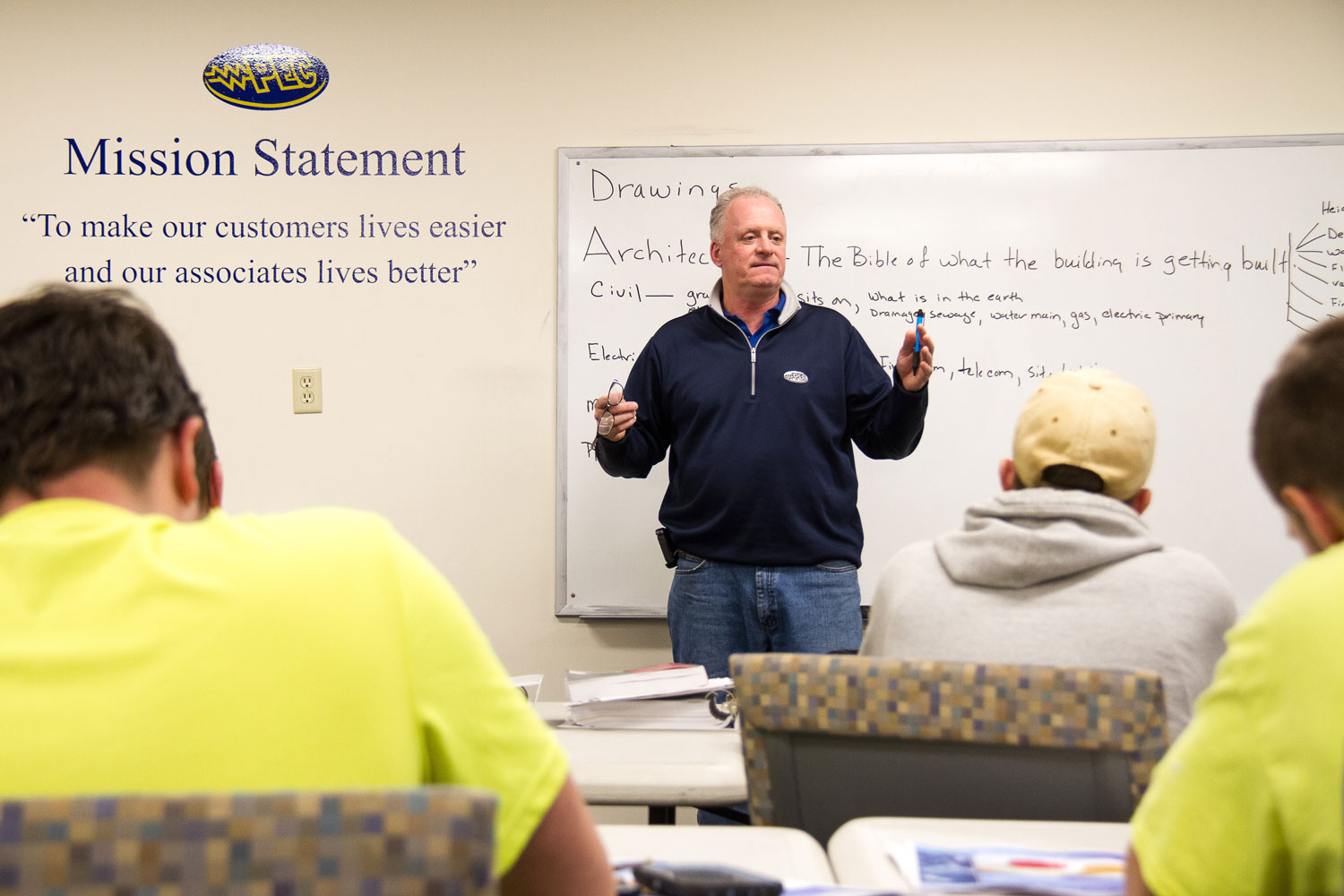

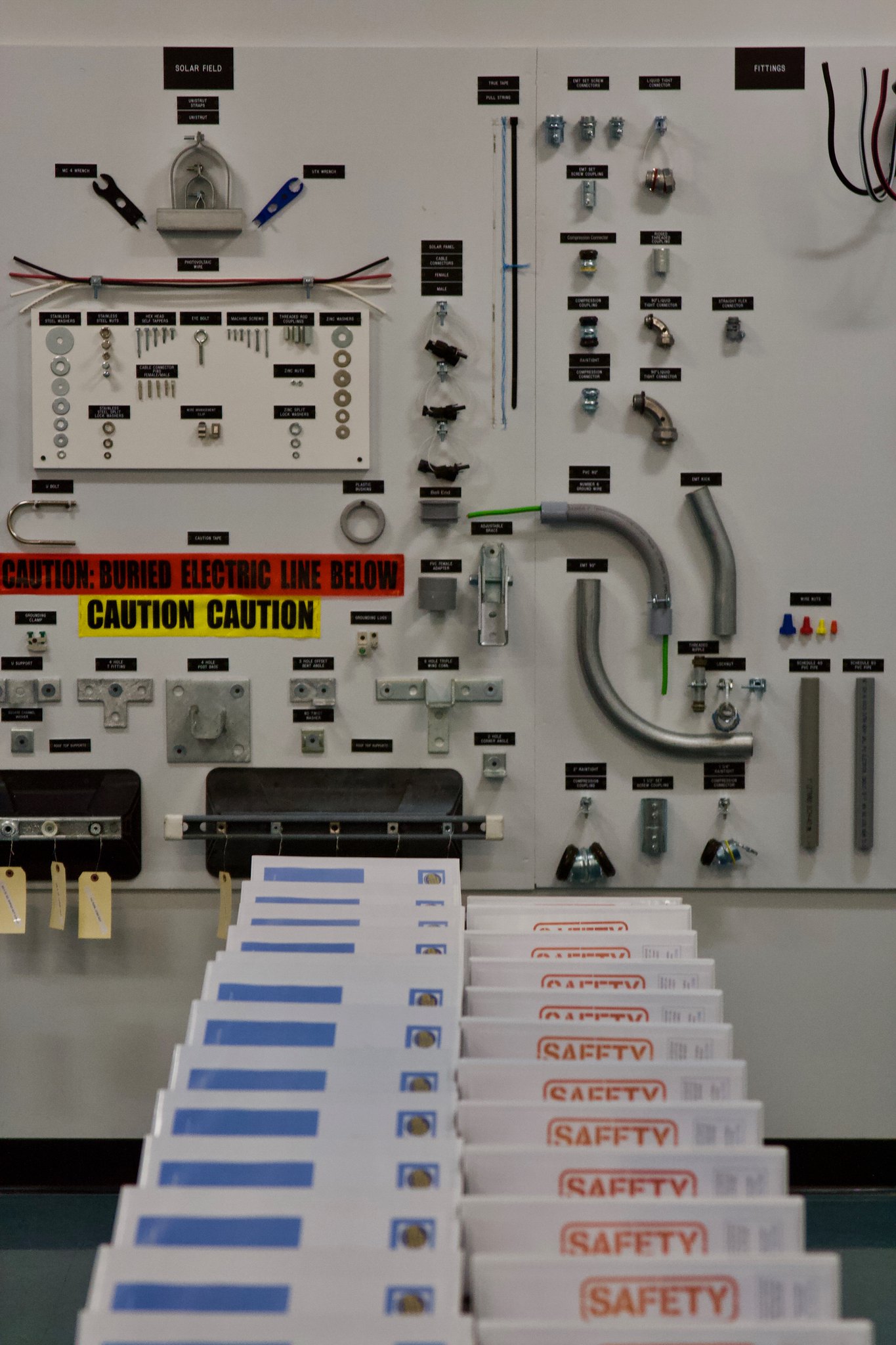

Safety & Training

Safety is a priority at PEC and an integral part of our company culture. PEC’s commitment to continuous improvement training and adherence to high standards result in a safer workplace. PEC associates follow all Company, State & Federal regulations, while adhering to the safety standards of both NFPA-70E & OSHA. In addition, our in-house training division provides the necessary certifications to keep our associates fluent in all safety practices and ensures they go home safe every day:

Accident Investigation

OSHA Construction Outreach

OSHA 30

NCCER Electrical Training

Excavation, Trenching & Soil Mechanics

Forklift

OSHA Safety and Health Management Systems

OSHA Standards for Construction

OSHA 10

NFPA-70E

NSC-Defensive Driving DDC4

Ramset

OSHA Record Keeping

OSHA Standards for General Industry

Certified Electrical Safety and Compliance

Lockout / Tagout

Fall Arrest

In-House State Board Certified Apprentice School

PEC is proud to provide a four-year in-house electrical apprentice program that is fully licensed by the Division of Professional Licensure and the Office of Private Occupational Education. The program is offered at no cost to our associates. Combined with our hands-on Field Development Program – our educational programs are second to none. A career in the electrical trade to become a licensed electrician not only provides for you in the here and now, is also sustains you for the future. “If you give a hungry person a fish, you feed them for a day, but if you teach them how to fish, you feed them for a lifetime” (Chinese proverb).